All You Need to Know About Alloy Wheels

What are alloy wheels?

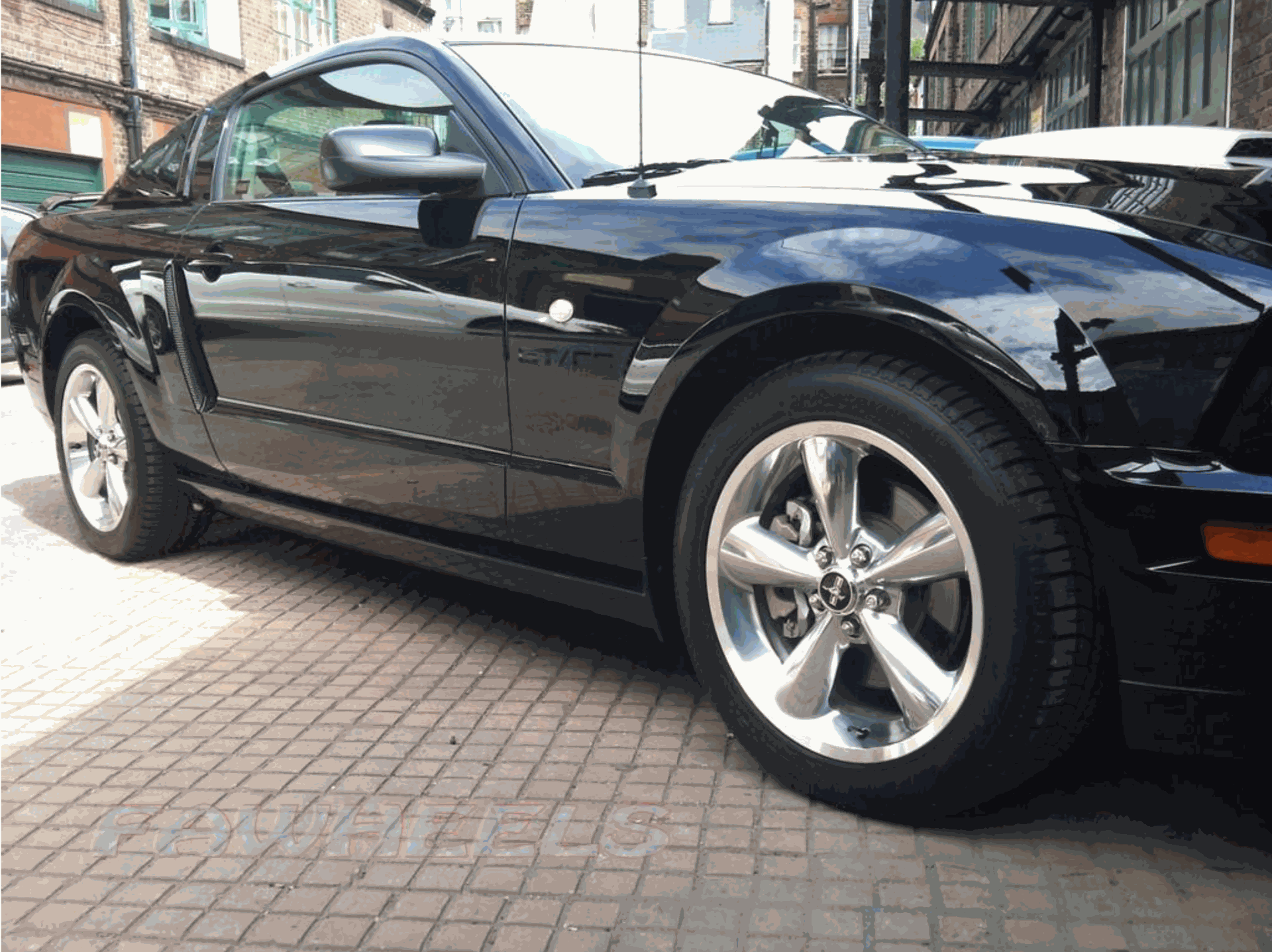

The term ‘alloy wheels’ refers to wheels which are produced from a mixture of aluminium and traces of other metals, a combination which helps to create a wheel that is very strong yet also lightweight. While they are more expensive than steel-plated wheels, they add a fantastic visual enhancement to your vehicle and they can increase a car’s overall value.

Aluminium on its own is rather lightweight, but when it is combined with other metals for the formation of alloy wheels, the entire product becomes substantially reinforced. They are primarily used in high performance vehicles, particularly those for racing purposes, although they have become a common sight on public roads in recent years.

The benefits of having alloy wheels

• They have a huge aesthetic appeal in comparison to steel wheels and hubcaps.

• They decrease a vehicle’s unsprung weight (weight not supported by the vehicle’s suspension), leading to better handling and acceleration.

• They increase brake clearance, which gives drivers greater control over deceleration.

• They are very durable due to the alliance of aluminium with other metals.

• The dispersal of heat reduces the likelihood of the wheels cracking or bending, as well as allowing for more efficient braking.

• They allow air to flow freely around all of the tyre, which helps to cool the brakes.

• They increase the value of your vehicle for all of the above reasons.

Alloy wheels vs Steel wheels

Alloy wheels

• Aluminium alloy can be cast and customised to a huge range of designs, giving cars a more bespoke, individual appearance.

• The mixture of aluminium and nickel is quite light, allowing for greater agility while driving and improved acceleration.

• This smoother drive makes driving on alloys quite enjoyable during the summer months.

• Alloy wheel covers can be polished, painted, machined or chromed to provide a sleek, classy appearance.

• Alloys are often the preferred option for motorists who want a high performance drive in an aesthetically outstanding vehicle.

Steel wheels

• Steel wheel designs tend to be generic and pragmatic.

• They are quite heavy, which makes them robust but less spectacular in terms of driving performance.

• They are more ideal for winter months, as their superior weight will bite snow harder and provide better grip.

• Steel wheel covers don’t have huge visual appeal and they can be prone to damage or coming loose entirely.

• Steel wheels tend to be more popular for no-frills drivers who simply want their vehicle to get them from point A to B.

Bespoke colour customisation is one of the many benefits of alloy wheels.What is wheel offset?

Wheel offset refers to the distance between the centreline and the hub mounting face at the back of the wheel. The offset figure is generally stamped or engraved on the wheel and is measured in millimetres of ET (deriving from the German word Einpresstiefe, literally translated as insertion depth). An offset reading falls into one of three categories – positive, zero or negative – depending upon the location of the mounting face.

• Positive offset wheels have their mounting face towards the front of the wheel and most front wheel drive cars fall under this category.

• Zero offset wheels have their mounting face even with the centreline of the wheel.

• Negative offset wheels have their mounting face towards the back of the wheel and most rear wheel drive cars fall under this category.

What is PCD?

Pitch circle diameters (PCD) refer to the diameter of a hypothetical circle drawn through the centre of a wheel’s bolt holes. It is measured in millimetres and indicates the number of studs or bolts that the wheel can have.

Taking Volkswagen as an example, their alloy wheels usually have a PCD of 4 x 100 (4 bolt holes drilled through the centre of an imaginary circle) or 5 x 100 (5 bolt holes drilled through the centre of an imaginary circle).

What is centre bore?

An alloy wheel’s centre bore refers to the size of the hole at the back of the wheel into which the hub fits. In order for the wheel to sit properly, the hole and the hub need to be exactly the same size.

The majority of contemporary wheels are hub centric, meaning that the hub protruding from your vehicle is load bearing – the studs and bolts simply secure the wheel in place onto the hub. With older, lug centre wheels, you will need to keep a sharper eye on your studs and bolts and replace them every once in a while. Ensure to tighten the wheels to roughly 75% of maximum tightness so that they are centred.

Find out the ideal wheel offset, PCD and centre bore for your car here.

How to fit alloy wheels

1. Ensure that you have the right type of bolts, as they are available in a large variety of diameters, threads and seatings.

2. Ensure that you have the 4 plastic spigot rings which help the interface between the wheel and the hub.

3. Ensure that your handbrake or parking brake is applied and then jack up your car.

4. Put a wheel up to your car and make sure that the bolt holes are aligned correctly, the wheel is correctly located on the hub and that there is wheel arch, suspension strut and brake arch clearance.

5. Tighten the bolts and nuts to the manufacturer’s specified torque – usually about 75% of maximum tightness.

6. Take the jack off your car.

How to find out alloy wheel sizes

To find out the diameter of your alloy wheels, check your tyre’s sidewall for an alphanumeric reading, which will usually read something like 205/45 R15. The latter figure refers to the radial diameter of the tyre, in this case 15 inches.

If you wish to find out the width of your alloy wheels, you will have to look at the wheel itself. Each alloy wheel has its size stamped into it – this is most often found on the inside of the wheel on the back of the spokes, although it can occasionally be visible on the wheel’s outside. The stamp will usually read something like 17 x 7, in which case the wheel is 7 inches wide and has a 17-inch diameter.

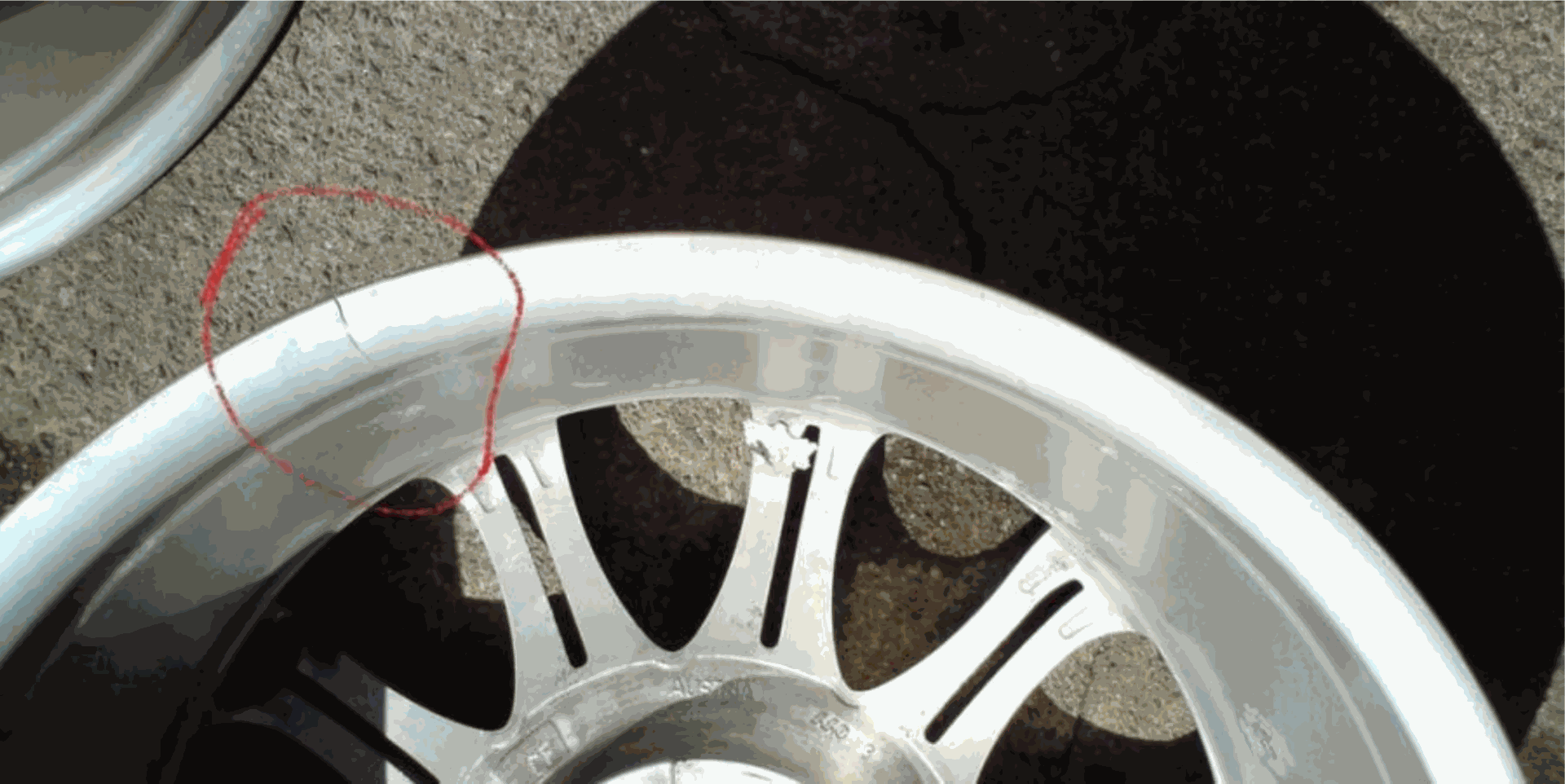

Typical alloy wheel damage

• Chipping: Alloy wheels can become chipped upon impact and visible small chunks are taken out of the wheel.

• Cracking: Any impact on alloy wheels while driving could cause the wheel to become cracked, which could be a serious problem. If a crack develops on a delicate part of the wheel, or grows to a substantial size, it is likely that the wheel will need to be scrapped.

• Corrosion: The reaction of the alloy wheel with salt on the road could cause the wheel to become corroded. Damage of this nature is normally identifiable by the appearance of white dust on parts of the wheel and could sometimes lead to structural damage.

• Kerb damage: Scraping your wheel off a kerb could cause substantial damage, the extent of which will vary depending on the nature of the wheel and the scale of impact with the kerb.

If you notice these, or any other, types of damage on your alloy wheels, it is likely that they will need a full refurbishment, a service that you can get from the team at First Aid Wheels.

Cracks such as this can be seriously problematic for alloy wheels.

How to avoid damaging alloy wheels

• Avoid hitting obvious dangers such as potholes, kerbs and raised manhole covers.

• If you regularly drive on a road that has any of these obstacles present, remember where you’ll come across then or perhaps consider taking an alternative route.

• Watch out for cars ahead of you to see if they swerve to avoid any obstacles.

• Be mindful of ‘freeze/melt’ cycles where water seeps into a crack and freezes, breaking up the concrete around it, before melting and causing the crack to expand into a full-blown pothole.

• Avoid puddles, full stop. It’s unlikely that you would drive into a puddle in any case, but be particularly mindful of it on potholed roads or after freeze/melt cycles. A seemingly miniature puddle could be concealing a substantial pothole.

• If you hit upon a sneaky pothole, or you have no alternative but to hit it, try to drive through it rather than being tempted to slam on the brakes. Driving straight through it will spread out any damage evenly across the whole wheel, whereas slamming a brake-locked wheel into it will concentrate the force of the impact on a particular area, which is more likely to damage the wheel significantly.

Bent wheel symptoms: warning signs to watch out for

• Unexplained vibration: If you feel a sudden, inexplicable vibration while driving, this could indicate a bent wheel. If the vibration comes from the steering wheel, the front wheels could be bent; or if a vibration is felt in the seat, it could be emanating from bent rear wheels. These are not exact diagnoses but they should help with troubleshooting the overall problem.

• Shaky steering: If your steering feels shaky or unresponsive, this is a definite red flag. Take corners and bends as smoothly as possible until you can get to a garage for a proper diagnosis, as tight cornering on a bent wheel could easily lead to tyre blowout.

• Punctured tyre: A bent alloy wheel will lead to a puncture if it is not treated. As the tyre sits flush against the wheel, even a slight bend in the rim will slowly leak air your tyre until it is rightly punctured.

• Bent rim: On an alloy wheel, a bent rim should be instantly noticeable. If you notice even a tiny bend, take your vehicle to a garage for further inspection.

Need alloy wheel refurbishment? Give First Aid Wheels a call